Microblast?

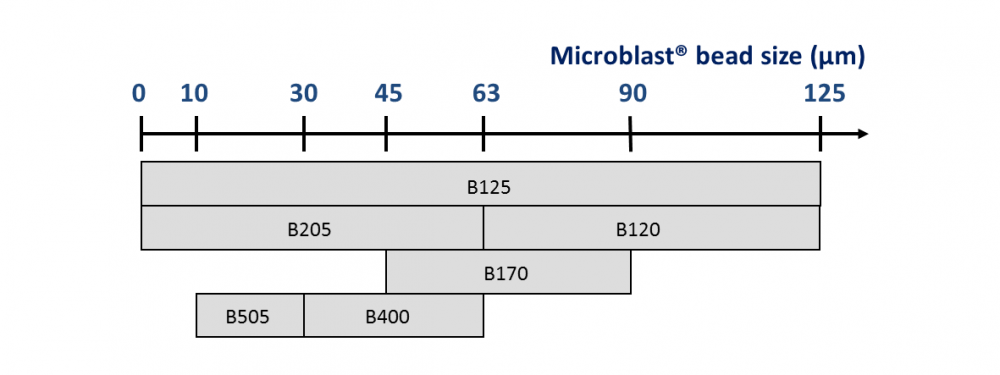

Part Number

- Microblast B120 63-125μm

- Microblast B125 1-125μm

- Microblast B170 45-90μm

- Microblast B205 1-63μm

- Microblast B400 30-63μm

- Microblast B505 10-30μm

Specification

The Industry Standard for Fine Ceramic Blasting Beads

Saint-Gobain ZirPro’s Microblast fine ceramic beads are used as blasting media for surface finishing applications. Microblast B205, B170 and B120 blasting beads deliver the smoothest finish and a unique satin effect on stainless steel, aluminum, titanium, magnesium and even plastic surfaces.

The Microblast product line is the industry standard in blasting media, delivering high-quality components with superior aesthetics in a variety of applications including automotive, aerospace, electronics, home appliances, sporting goods and architecture. With their unique characteristics, Microblast ceramic beads also are used for precision blast cleaning applications to achieve the smoothest and most uniform surface finish on treated parts.

Engineered fine ceramic blasting media

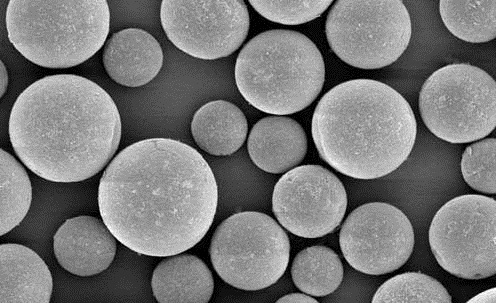

Microblast fine ceramic beads are produced through a unique proprietary process developed over many years by ZirPro engineers. Microblast ceramic blasting media are characterized by:

- Extremely tight particle size distributions

- Refined spheroidal bead shapes

- High mechanical strength

The combination of these unique features ensures media integrity and durable performance during blasting operations. Microblast fine ceramic beads are easy to handle in all categories of pressure blasting equipment. Their unique physical features make them the most stable fine media to project and recycle in blasting processes. Microblast is available in standard size ranges.Specific size ranges can be supplied upon request. Packaging is 25 kg plastic containers or big bags.

Engineered to the highest standards of quality

To deliver the highest and most consistent standards of quality, Microblast fine ceramic beads undergo a fully controlled process as well as a stringent product quality inspection through advanced technologies such as particle size laser diffraction and morphological imagery. This enables ZirPro customers to achieve blasted components with perfect and stable surface finishes.

Contact us to learn more ! https://www.zirpro.com/zirconia-beads-powders/microblast