Resin double-face grinding wheel

Resin double-faced grinding wheels have a wide range of versatility. The products are mainly used for large-scale surface processing of small and medium-sized parts, such as bearings, automotive parts (piston rings, connecting rods, clutch discs), springs, tools, electronic molds (mobile phone parts) and castings.

Norton resin double-face grinding wheel adopts Saint-Gobain's advanced B18 and B98 bonding technology. Compared with domestic and imported similar products, the service life of the grinding wheel is increased by 2-5 times and 1-3 times respectively, which greatly reduces the dressing frequency of the grinding wheel. The number of workpieces that can be processed during the trimming interval is increased, the user's productivity is increased, and the overall grinding cost is reduced.

Saint-Gobain Abrasives can be designed according to the actual processing requirements of the user for the grinding wheel formulation and surface grooving. The resin double-end grinding wheel has a complex mounting bolt hole distribution surface. The strict manufacturing process of Saint-Gobain Abrasives ensures that the bolt positioning accuracy is between +/-0.1mm, which is suitable for installation on most imported machine tools. At the same time, the grinding wheel has a good balance level, which can avoid vibration during the grinding process, so that better surface quality and machining accuracy can be obtained.

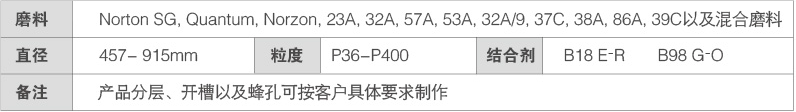

Specification

Feature